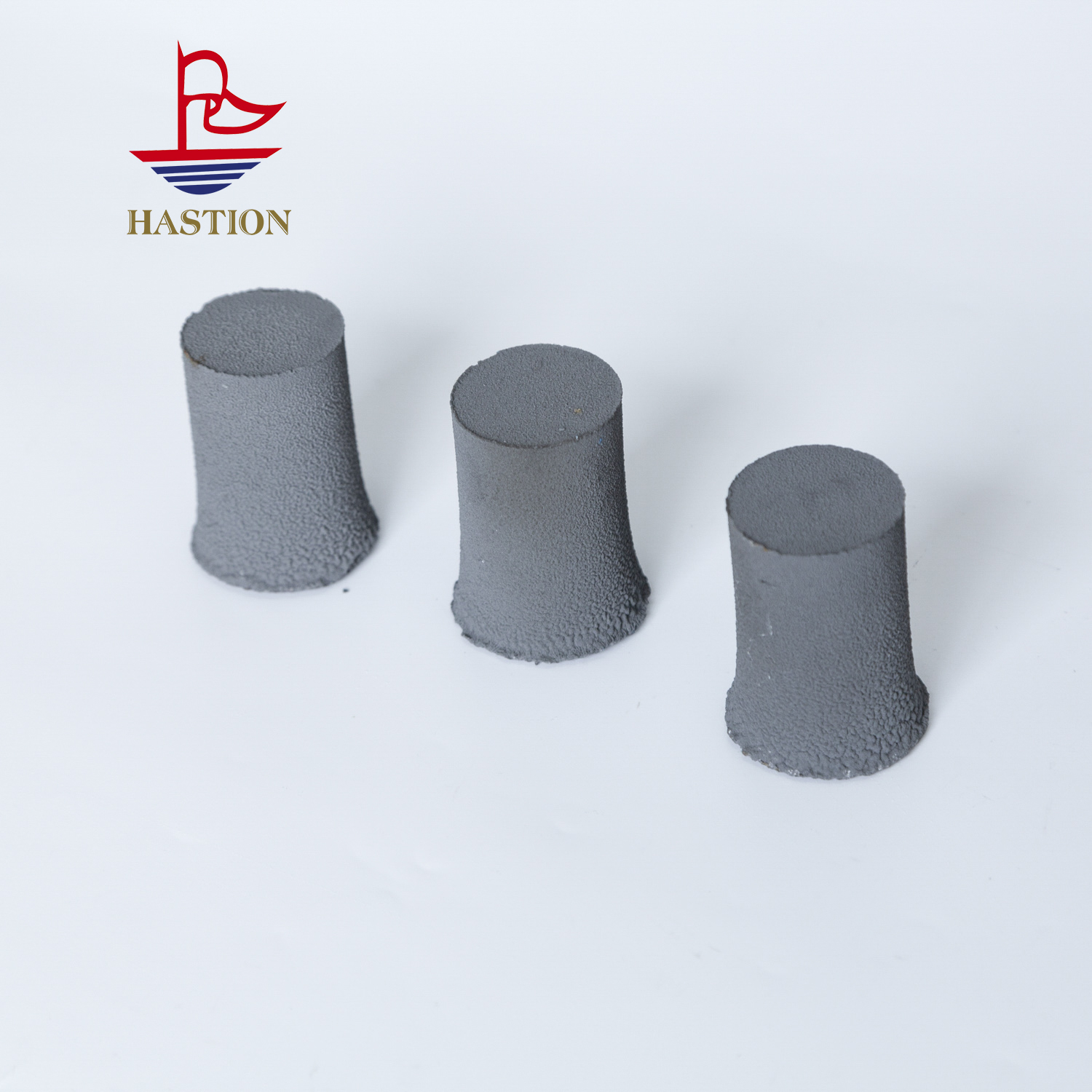

High-strength titanium carbide rods - for ceramic processing

The manufacturing process of this round bar is highly stringent, encompassing rigorous control over the purity of titanium carbide powder (purity ≥99.5%) and precise regulation of sintering temperature (approximately 1500 °C), with each step critically influencing the final product performance. The finished material exhibits exceptional dimensional stability; its coefficient of thermal expansion is only 6×10⁻⁶/°C across a temperature range of -50 °C to 300 °C—significantly lower than that of conventional metallic materials—ensuring dimensional accuracy of precision tools under diverse operating conditions. It is widely employed as wear-resistant inserts in automotive molds, where it withstands prolonged high-pressure friction with minimal wear, thereby extending mold service life. Titanium carbide round bars made from cemented carbide also possess excellent electrical conductivity, making them suitable for use as electrodes in electrical discharge machining (EDM). In EDM applications for precision mold fabrication, these electrodes demonstrate low wear rates and enable high processing accuracy. Furthermore, the material exhibits superior fatigue resistance and is resistant to cracking under repeated impact loading, rendering it ideal for components subjected to high-frequency vibrations. In the nuclear energy sector, owing to its outstanding radiation resistance, it is frequently utilized as a cutting or processing tool for internal reactor components.

在线联系供应商

Other supplier products

| Industrial titanium carbide rods for precision molds | Compared with traditional high-speed steel bars, the cutting speed of hard alloy titanium carbide round bars can be increased by 3 to 5 times, whic... | |

| Titanium carbide powder with enhanced wear resistance | Titanium carbide powder can be mixed with other carbide powders (such as tungsten carbide and vanadium carbide) to form multi-component composite p... | |

| Titanium carbide hard alloy guide wheels for industrial use | This type of guide wheel can be customized with groove shapes according to the specifications of the wire or pipe, such as V-shaped, U-shaped, semi... | |

| High-density tungsten carbide round rods | The product is mainly used for heavy machinery gear tunneling of roadheader which plays an important role in improveing boring machine life. It can... | |

| General-purpose cutting tool titanium carbide hard alloy round bar | The production process of this round bar is highly rigorous, encompassing strict control of titanium carbide powder purity (≥99.5%) and precise ... |

Same products

| 3D printing spherical titanium carbide powder | 卖方: 株洲华斯盛高科材料有限公司 | This batch of titanium carbide powder (TiC) has a purity of over 99.5%, with a particle size cont... | |

| Titanium carbide hard alloy drive wheel - Specialized | 卖方: 株洲华斯盛高科材料有限公司 | The titanium carbide (TiC) guide wheel is fabricated via high-temperature powder metallurgy sinte... | |

| Industrial guide wheels, titanium carbide wear-resistant alloy | 卖方: 株洲华斯盛高科材料有限公司 | This carbonized titanium (TiC) guide wheel is formed by high-temperature sintering of 99.5% pure ... | |

| Unfinished bar stock - heat treatable | 卖方: 株洲华斯盛高科材料有限公司 | This high-purity titanium carbonitride (TiCN) round bar is fabricated via hot-pressing and sinter... | |

| Steel-based titanium carbide hard alloy round bar | 卖方: 株洲华斯盛高科材料有限公司 | This carbonitride round bar (TiC) is formed by hot-pressing and sintering 99.5% high-purity carbo... |