HDPE Water and Gas Supply Pipe Line

HDPE Water and Gas Supply Pipe Line

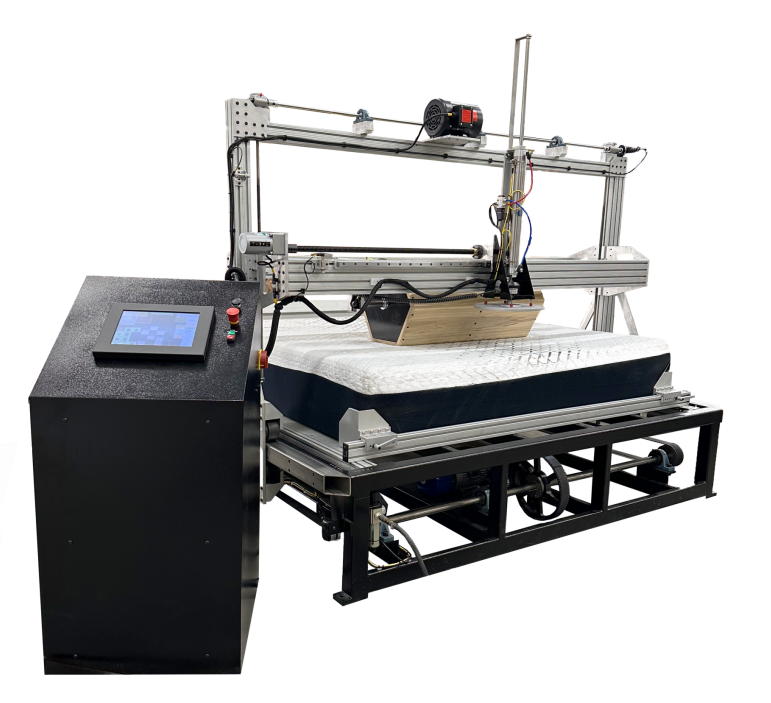

This extrusion line designed by our company selected special extruder and adopted computer control. The screw has barrier unit and special material mixing components and barrel has new style grooves that achieve good plastication and mixing effect. The complete line assured great output and stable production. In addition, this line is equipped with special extruder for marking line of PE pipes.The extrusion line adopts the most advantaged spiral and lattice die head in the world, which assured stable extrusion in production process. In order to fit the performance of PE material and assure high production speed, we adopt water film lubricating and water circulation cooling. It has ellipse rectify device when producing huge diameter pipes. It has special designed vacuum and cooling devices that make good effect of huge diameter pipes extrusion.Haul off machine adopts three and six pedrails with European speed control system makes hauling stable and reliable. Cutting adopts planetary saw. The complete line has a high computer automatically control degree and long life span without maintenance. HUASU designed and developed this line on the basis of many years’ experience. We can do diameter scope from 12mm to 630mm, which widely used for water supply and gas distribution.

Features of HDPE water and gas supply smooth pipe line:

1.BM screw ensures high prevision, low energy consumption. Extruding is stable and capacity is big.

2.Two grade vacuum cooling calibrating system of high speed and negative pressure. Spraying system with high intensity ensures even cooling of pipes.

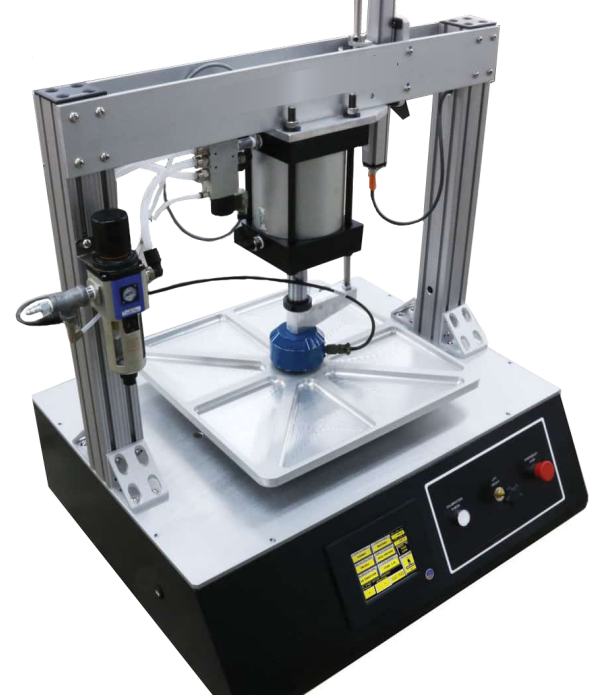

3.Calibrator of pipe extruder: Equipped with multi-section water membrance cooling system which meets the requirement of thicker wall pipe or large diameter pipe extrusion with high speed and by adopting an automatic liquid level and vacuity control system, one high quenching spray water cooling system with cooling baths made of stainless steel to ensure pipe cooling equably and optimum cooling result.

4.Caterpillar haul-off unit of pipe extrusion line: Equipped with an automatic clamping mechanism and haul-off speed adjusted by PLC control system which ensure haul-off speed with the whole speed controlled synchronously

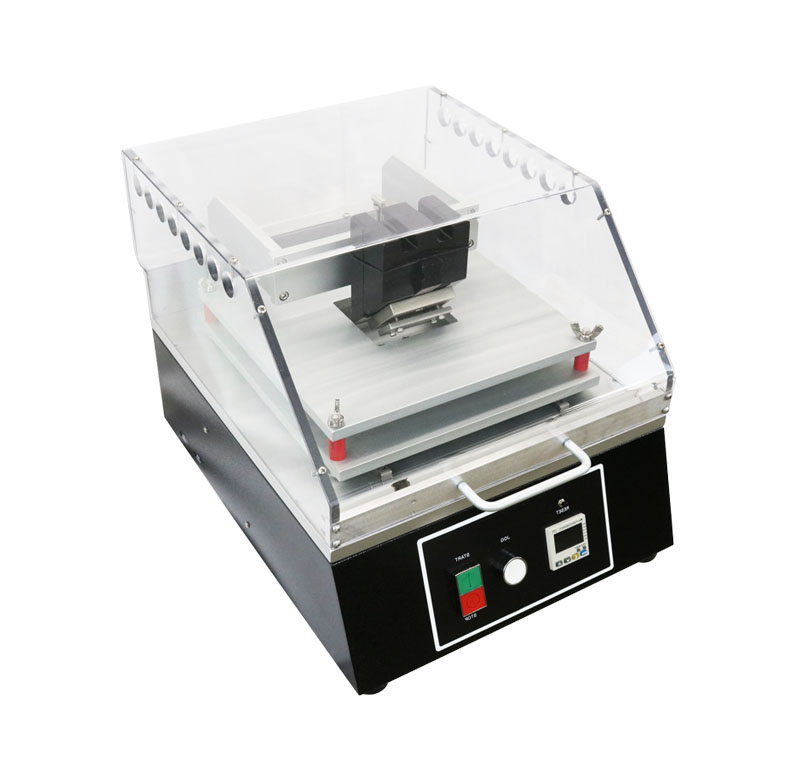

5.Cutter of PE pipe machinery: By adopting one planetary cutter for smooth cross section of cutting surface with lower noise and non-hips left by using on dust collector to allow a clean working condition.

Other supplier products

All supplier products

Same products