IEC62133 & UN38.3 Battery Crush / Squeeze Test Equipment

Applications

Test battery safety performance through crush, after test the sample shall not explode or catch fire.This equipment becomes necessary inspection equipment for the battery manufacturer and researcher.

Standard Compliance

MT/T1051-2007 Lithium-ion batteries for cap lamp --Crush Test

UL 1642Lithium Batteries --Crush Test

UL 2054Lithium Batteries

GB/T 2900.11-1988Terminology of (secondary) cell or battery

YD 1268- 2003 The safety specification and test method for lithium batteries and charger--crush test

SJ/T 11169-1998Standard for lithium batteries crush test

GB/T 8897.4-2002Primary batteries: Safety of lithium batteries --crush test

SJ/T 11170-1998Standard for household and commercial batteries --crush test

YDB 032-2009Back-up Lithium-ion battery for telecommunications

QB/T 2502-2000 General specification of lithium-ion battery --crush test

Specifications

1.Factory direct sale

2.Certificate:ISO

3.Can be customized

4.Good after-sale service

5.Warranty: 12 months

Features

1.The wire enclosed with metal fire-proof cover, which is available to prevent the flame during testing process.

2.Lighting system is designed to observe the internal testing process;

3. Nail Penetration/Crush Force controllable within range from 250N to 13KN ,meet different standards;

4.Wire hole provides a possibility to test internal temperature or air pressure while vent hole with air blower can discharge the exhaust air.

5.Control system employs independent control cabinet & separated with the test chamber with a distance 1-2 meter, which can reduce the noise and improve safety.

Technical Parameters

|

Model |

BE-6045 |

|

Pressure(KN) |

20 |

|

Max. Displacement(mm) |

200,300,500 |

|

Additional Function(Optional) |

Voltage, Temperature Sampling, Camera Monitoring system, Fire-extinguishing system, explosion-proof system, smoke evacuation system |

|

Crush Speed |

0 ~ 40mm/min(Controllable ) |

|

Testing Space (mm) |

200X200X200MM, 300X300X300MM or Customize |

|

External Dimension |

W680 X D570 X H1740 |

|

Optional Function |

|

|

Power |

0—10V,0--100V |

|

Temp. Sampling Range |

0 ~ 1200℃ |

|

Power, Temperature Accuracy |

±1%FS |

|

Voltage Resolution |

1mV |

|

Temp. Resolution |

0.1℃ |

|

Main Technical Parameters |

|

|

Speed |

0 ~ 40mm/min(Controllable ) |

|

Crush Range |

0—300MM optional |

|

Structure |

Vertical&horizontal (select according to actual size) |

|

Testing Condition |

Applied force of 13KN, once the maximum pressure has been obtained it is to be released. |

|

Crush Method |

Vertical, Horizontal |

|

Crush Deformation |

No (Computerize can be customized) |

|

Crush Remaining Time |

0~99 hours 99 mins 99 seconds |

|

Driven Method |

Hydraulic |

|

Crush Accuracy |

±1% |

|

Structure |

|

|

Cabinet |

Independent vertical & horizontal test machine and control system |

|

Communication |

No (Computerize can be customized) |

|

Crush Clamps |

Planer crush tray, fixtures in different size upon the different standard |

|

Data Capture Module |

Independent remote sampling, multi voltage, temp.,current acquisition channels (optional ); |

|

Standard Channel Quantity |

2-channel,4-channel,8-channel,various data acquisition system (optional ) |

|

Camera Monitoring System |

Test zone installed with high definition camera monitoring system in remote control with explosion-proof (optional). |

|

Standard Configuration |

Crush machine 1 set, control cabinet 1 set, crush tray/1 pcs |

|

Testing Clamp |

Customize according to actual operating condition. |

|

Power |

AC380V 50HZ 3 Phase 5 Wire |

|

Working Condition |

0℃~45℃ |

Send product request

Other supplier products

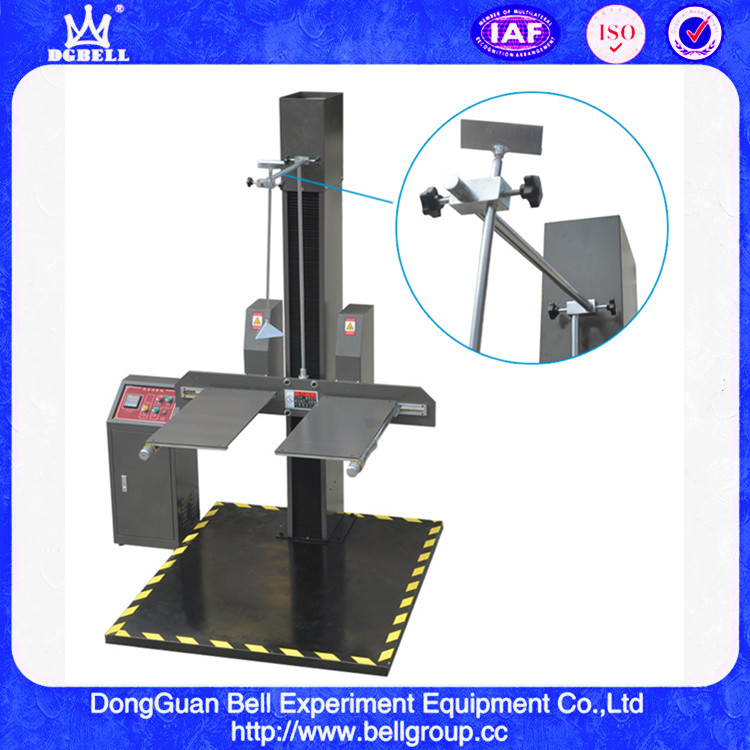

| Double Wings Package Drop Impact Tester Drop Testing Machine BF F 415D | Applications Drop Impact Test machineis to test large and heavy package products’ drop impact performance throughsimulate real face ,edge and... | |

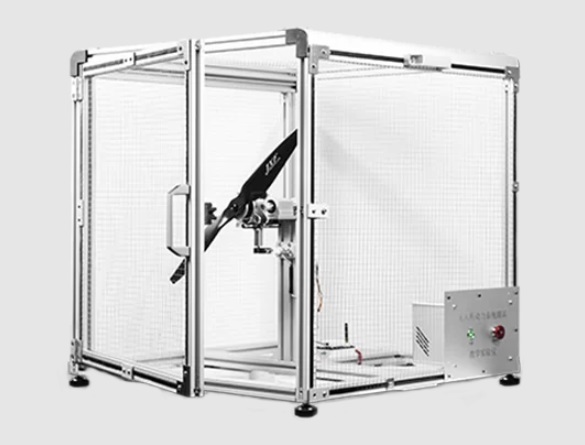

| UL1642 Battery Squeeze Machine Nail penetration Testing BE 6047 | Application To test battery safety performance by crushing & nail-penetration through real-time test data ( battery voltage, max. battery tempe... | |

| IEC62133 & UN38.3 Battery Crush / Squeeze Test Equipment | Applications Test battery safety performance through crush, after test the sample shall not explode or catch fire.This equipment becomes necessary... | |

| 5KNS / 10KNS/ 50KNS 600KNS Customized Universal Tensile Streigth Test Machine | Application This equipment is designed and manufactured tomeasure & test tensile strength, compression strength, peeling strength, tearing... | |

| 2 or 3 Zone Constant Temperature Thermal Shock Chamber Testing Machine | Applications This equipment is widely applied for electronic and electric products, components and materials by constant high low temperature, temp... |

Same products

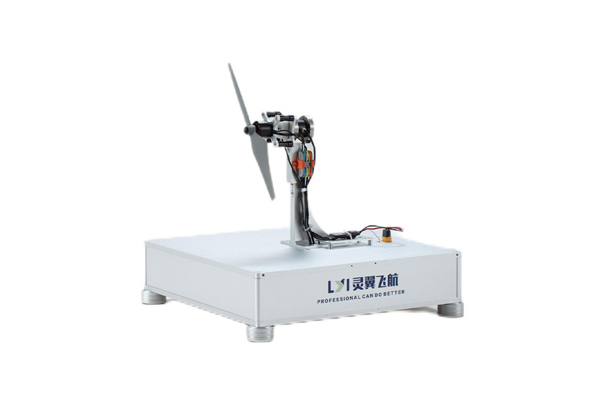

| WF-EDU-02 Motor & Propeller Test Kit | Seller: Wing Flying Technologies Co., Ltd | WF-EDU-02 Motor & Propeller Test Kit Product Description Motor & Propeller Test Kitsare... | |

| WF-EDU-01 Motor and Propeller Test Kit | Seller: Wing Flying Technologies Co., Ltd | WF-EDU-01 Motor and Propeller Test Kit Product Description Suggested Propulsion system ... | |

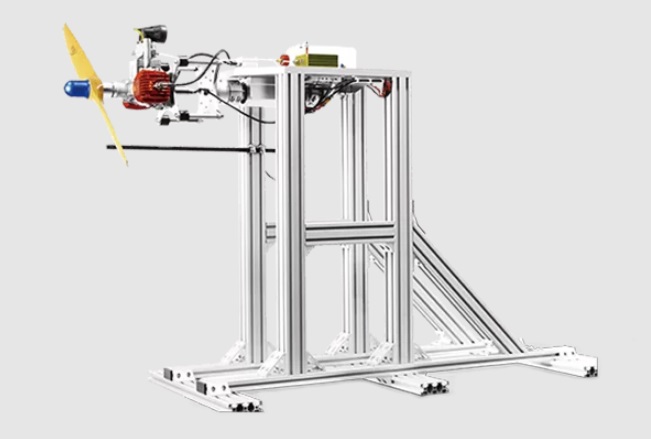

| WF-EN-50 Engine Test Bench | Seller: Wing Flying Technologies Co., Ltd | Suggested Engine 110cc-350cc Engine Max Hanging Type Engine 20kg ... | |

| WF-EN-15 Engine Test Bench | Seller: Wing Flying Technologies Co., Ltd | WF-EN-15 Engine Test Bench Product Description Suggested Engine 110cc Engine ... | |

| BS EN 12600 Two Tyres Impactor | Seller: Qinhuangdao Yuanchen Technology Equipment Co., Ltd. | Reference Standard: BS EN 12600:2002Glass in building – Pendulum test – Impact test m... |