5KNS / 10KNS/ 50KNS 600KNS Customized Universal Tensile Streigth Test Machine

Application

This equipment is designed and manufactured tomeasure & test tensile

strength, compression strength, peeling strength, tearing strength, shearing strengthwith accurate measuring &testing performance forsemi-finished products, finished productsinmetal, plastic, rubber, textile, synthetic chemical, wire & cable, leather industriesetc.

STANDARD COMPLIANCE

GB/T16491-1996 Electronic Universal Testing Machine

GB/T12160-2002 Calibration of Extensometers Used In Uniaxial Testing

GB/T16825-1997 Verification of Tensile Testing Machines

ASTM D903 Adhesives Peel Strength Testing

GB/T2790 Adhesive, 180° Peel Strength Test Method Specimen Assembly

GB/T2791 Adhesives, T peel strength test method for a flexible-to-flexible test specimen assembly

GB/T2792 Test method for peel strength of pressure-sensitive tape at 180° angle

CNS11888 Method of Test for Pressure Sensitive Adhesive Tapes and Sheets

JIS-K6854 Adhesives -- Determination of peel strength of bonded assemblies

PSTC7 Holding Power of Pressure-Sensitive Tapes Available from PSTC (Pressure Sensitive TapeCouncil)

Specifications

1.Factory direct sale

2.Can be customized

3.Good after-sale service

4.Computer type

Technical Parameters

|

Model |

BF-BL-5KNS |

|

Max. Testing Force |

500kg /5000N |

|

Unit |

Kgf, N,LB |

|

Operating Method |

Button Input & Digital Display (Computer with Software System as optional) |

|

Test Resolution |

1/10000 |

|

Test Accuracy |

≤±0.5% |

|

Test Velocity |

0-300mm/min (Controllable) |

|

Velocity Accuracy |

±1% (of reading value) |

|

Test Spacing |

600mm( without Testing Fixture) |

|

Test Width Approx. |

120mm |

|

Loading Sensor |

0.5 Grade High Precise Force Sensor |

|

Accuracy Class |

1 Grade |

|

Test Range |

0.4% ~100% Full Scale |

|

Displacement Display Accuracy |

±1% (of Reading Value) |

|

Displacement Resolution |

0.005mm |

|

Motor Power |

0.37KW |

|

Power Input |

220V, 50Hz,Single Phase (Special Power Input can be customized) |

|

Overall Dimension (L×W×H) |

Approx. 640×450×1200mm |

|

Gross Weight Approx. |

90kg |

Send product request

Other supplier products

| 5KNS / 10KNS/ 50KNS 600KNS Customized Universal Tensile Streigth Test Machine | Application This equipment is designed and manufactured tomeasure & test tensile strength, compression strength, peeling strength, tearing... | |

| Comprehensive Environmental Temperature Humidity Vibration Testing Machine | General Intraduction This equipment complied with national standard, able to satisfy special testing requirements ,is widely applied for electronic... | |

| UL1642 Battery Squeeze Machine Nail penetration Testing BE 6047 | Application To test battery safety performance by crushing & nail-penetration through real-time test data ( battery voltage, max. battery tempe... | |

| IEC62133 & UN38.3 Battery Crush / Squeeze Test Equipment | Applications Test battery safety performance through crush, after test the sample shall not explode or catch fire.This equipment becomes necessary... | |

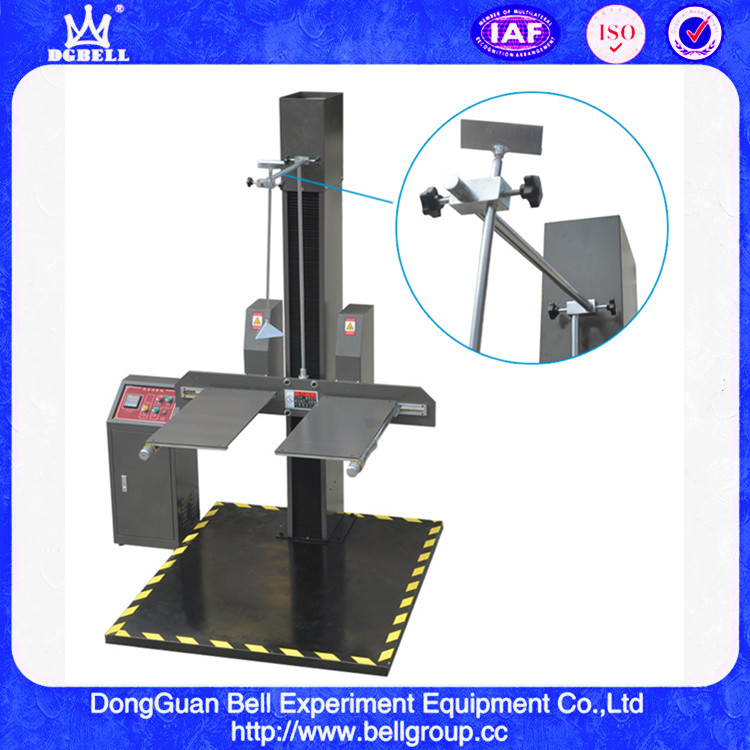

| Double Wings Package Drop Impact Tester Drop Testing Machine BF F 415D | Applications Drop Impact Test machineis to test large and heavy package products’ drop impact performance throughsimulate real face ,edge and... |

Same products

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... | |

| Flame retardant testing machine | Seller: Qinsun Instruments Co., LTD | Feature highlights: Flame Retardant Tester is designed for testing plastic runway surface layers... |