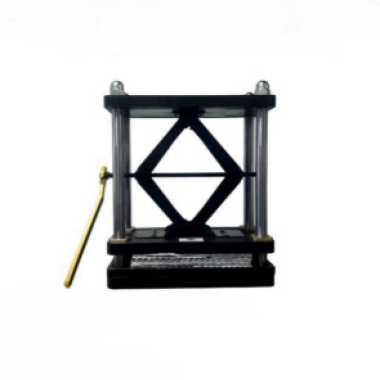

Rubber hose outer coating wear testing machine 丨 Rubber Hose Abrasion Tester

Product Introduction:

Rubber hose outer coating Wear testing machine for hydraulic hoses and other similar types of hoses with fabric or steel wire reinforced outer coating with a smooth and flat surface.

Test method:

1. Install the assembled sample and mandrel on the test device, and ensure that the sample has no axial movement and (or) rotation.

2. place the abrasive tool to make contact with the sample, apply the vertical static pressure F specified in the product standard, and start the machine. If the force F is not specified in the product standard, the applied vertical static pressure should be 50N±0.5N.

3. the test is carried out until the specified number of cycles is completed, and then the sample assembly is removed from the test device, and the sample with or without a core shaft is weighed again as the initial weighing. It is important to remove any particles attached to the outer coating before weighing.

Test standard:

GB/T 12721-2007 - Determination of abrasion resistance of rubber hose outer coating

ISO 6945:1991 - Determination of the abrasion resistance of rubber hose cladding

KS M ISO 6945-2013 - Determination of the abrasion resistance of the outer coating of rubber hoses

EN ISO 6945-1996 - Determination of the abrasion resistance of rubber hose outer coatings

DS/ISO 6945-1984 Determination of wear resistance of rubber hose cladding

Main parameters:

1. reciprocating frequency: 1.25Hz(45 RPM)

2. cycle stroke: 200mm

3. loading static pressure: 50N±0.5N(other pressure weights can be customized processing)

4. Mandrel length: 150mm

5. shaft diameter: 5mm, 8mm, 10mm, 13mm, 16mm, 19mm, 22mm, 25mm, 32mm, 38mm, 45mm, 51mm, optional three, can also provide dimensional processing

Send product request

Other supplier products

| MARK-II Slip Resistance Tester ASTM F1677 | Product Introduction: Paste the cut sample on the test fixture of the portable MARK-II anti-slip testing machine, put down the weight of the rotat... | |

| Oxidation Induction Phase Analysis Tester / Oxidation Induction Tester | Differential Scanning Calorimeter DSC is designed to determine the inner heat transition relating to temperature and heat flow, it is widely used i... | |

| Yellowing resistance test chamber | Durable & Reliable | Applicable standards HG/T3986. ASTM D1748. etc. Scope of application Test method for determining the yellowing resistance of light and white pro... | |

| DIN EN 13759 Infant Dummy 110kg For Testing Upholstered Furniture | Product Details Place of Origin: China Brand Name: STD Certification: Calibration Certificate Model Number: STD-SL-T610F ... | |

| Multilayer geotextile single-layer thickness tester丨IS0 9863 | Meet the standard GB/T17598-1998. GB/T 13761.1-2022. JTG E50-2006. IS09863-90 Scope of application The multi-layer sample is mechanically separa... |

Same products

| Briefly describe the importance, core functionality and how to implement a hospital clock system solution | Seller: California Triangle | In the healthcare industry, precise time synchronization is critical. Every second can be a matte... | |

| Sand and Dust Test Chamber for Automotive Connectors | Seller: Standard International Group (HK) Limited | Operating Conditions: Ambient temperature: 5°C~+28°C (average temperature within 24 hour... | |

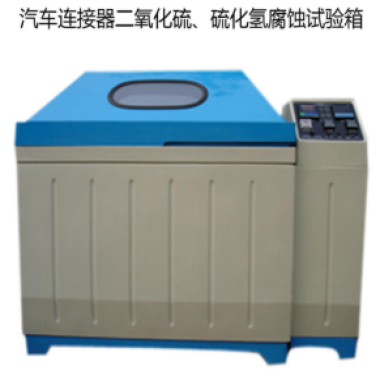

| Automotive Connector SO₂/H₂S Corrosion Test Chamber | Seller: Standard International Group (HK) Limited | Standards: GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosio... | |

| Automotive Connectors Salt Spray Tester | Seller: Standard International Group (HK) Limited | Applicable Standards: Neutral Salt Spray (NSS) Tests: GB/T2423.17. ISO 3768/3769/3770. ASTM B117... | |

| Air - tightness Testing Device for Automotive Connectors | Seller: Standard International Group (HK) Limited | Main Functions: 1. Provide stable positive and negative pressures for testing the air - tightnes... |